Delving into the realm of advanced technology, the world is witnessing a significant shift in the field of semiconductor repair. The rise of robotics has dramatically revolutionized this landscape, enhancing precision and minimizing the scope of human error. By replacing traditional, manual methods, these automated solutions have streamlined maintenance tasks, making them more efficient. The success stories of these robotic implementations, spread across several sectors, are a testament to their potential. This prompts an in-depth look into the impact of such innovations on the semiconductor industry, the benefits they bring to manufacturing processes, and how they contribute towards the aim of zero-defect products. Further, with the advent of artificial intelligence and machine learning, the integration of these advanced technologies into semiconductor solutions could potentially redefine the future of this industry.

Revolutionizing precision with robotic semiconductor repair

In the realm of advanced technology, innovative strides are being made in the area of robotic semiconductor repair. One of the most significant milestones is the impact of robotics on the enhancement of precision and quality in semiconductor repairs.

Implementing robotics for enhanced precision in chip repair

The advent of new technologies, such as computer vision, has been instrumental in facilitating robotized diagnostics and semiconductor repairs. High-quality robotic systems, armed with these technologies, have been successful in the miniaturization of semiconductor components. This has been a game-changer for the industry, presenting a breakthrough in the pursuit of precision and quality.

Automated solutions for minimizing human error in semiconductor maintenance

The integration of robotics in semiconductor maintenance has effectively minimized the margin for human error. By developing autonomous robotic systems for predictive maintenance and repair of industrial semiconductor equipment, industries are witnessing a rise in efficiency and productivity.

Case studies : success stories of robotics in semiconductor repair

The use of artificial intelligence in optimizing robotic repair processes for semiconductors has been a notable success in the field. Moreover, innovations in robotic materials and techniques are prolonging the lifespan of semiconductors, further revolutionizing the semiconductor repair industry.

Enhancing efficiency in semiconductor manufacturing through automation

Automation has had a profound impact on the semiconductor industry, fundamentally reshaping manufacturing processes and operational efficiency. The implementation of intelligent robots has revolutionized the precision of quality control, resulting in substantial cost reductions. With this transformative technology, the intricacies of semiconductor production can be navigated with unparalleled accuracy and speed, driving productivity to new heights.

Benefits of automation extend beyond productivity and cost-effectiveness. Automated systems have significantly improved the safety and efficiency of maintenance operations in semiconductor factories, reducing downtime and preventing costly errors. The evolution of semiconductor products has been accelerated by these innovative manufacturing techniques, setting the stage for a new era of technological advancement.

Fascinatingly, the automation revolution in semiconductor manufacturing is not just about robots replacing manual labor. It’s an intricate dance of data, algorithms, and finely-tuned machinery working in concert to produce the tiny electronic brains that power everything from smartphones to self-driving cars. With the advent of sophisticated automated systems, the future of semiconductor manufacturing appears to be one of increased efficiency, reduced costs, and enhanced product quality.

Robotic innovations: a leap towards zero-defect semiconductor products

Advancements in the realm of robotics have proven instrumental in elevating the quality of semiconductor products and minimizing failure rates. By harnessing cutting-edge robotic technologies, detection and ultra-precise repair of semiconductor defects have become a reality. High-end products now benefit from semiconductors whose components have been miniaturized by advanced robotic systems, resulting in a more competitive market.

Moreover, the integration of artificial intelligence into robotics is transforming semiconductor production lines, paving the way for an era of defect-free manufacturing. This shift towards sustainable development in the semiconductor manufacturing processes is a testament to the power of robotic innovations. Furthermore, the evolution of predictive maintenance through robotics marks a significant stride towards optimizing the lifespan and reliability of semiconductor products. The repair of your robotic semi-conductor production machines has become more efficient and effective, further improving the quality of semiconductors.

Integrating advanced robotics into wafer handling and repair processes

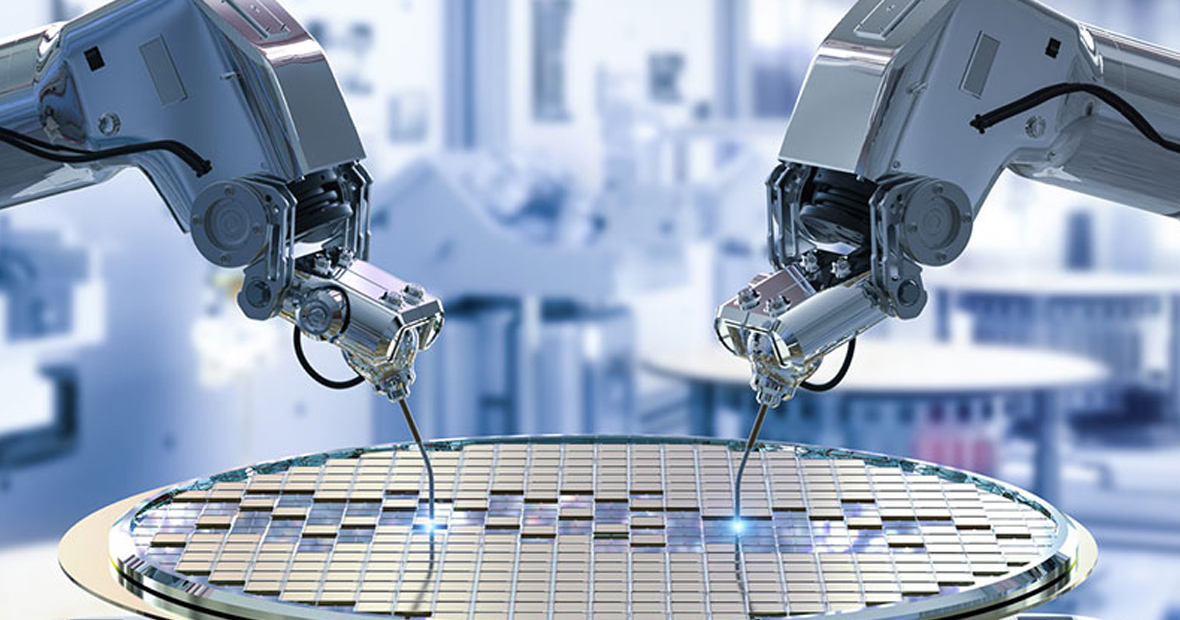

Advancements in robotics have become a key player in the field of semiconductor repair technologies. Notably, the integration of advanced robotics into wafer handling and repair processes has become paramount. The importance of robotic precision in these processes cannot be overstated. It guarantees accurate wafer manipulation and minimizes error, leading to superior semiconductor production.

Moreover, the advent of advanced vision systems has revolutionized the way wafer defects are identified and rectified. These innovative systems employ artificial intelligence to precisely detect and correct even the most minute wafer defects, thereby enhancing the overall quality of semiconductors. Additionally, robotic automation streamlines workflow in semiconductor repair, ensuring efficient and seamless operations. This is particularly beneficial in improving material management and reducing contamination risks, which are integral to maintaining high standards in semiconductor production.

Furthermore, cutting-edge technology is being leveraged for robotic wafer repair. Techniques such as laser and micro-welding are used to deliver precise and effective repair solutions, further reinforcing the pivotal role of robotics. The evolution of robotic handling processes seeks to increase production capacity and reliability of semiconductors, marking a significant step forward in the industry. Thus, the integration of robotics is not just about improving current processes but also about paving the way for future advancements in the field of semiconductor repair technologies.

Future trends: ai and machine learning in robotic semiconductor solutions

As the era of digital transformation unfolds, artificial intelligence (AI) and machine learning are shaping the future of robotic semiconductor solutions. With constant evolution and advancement, AI has become instrumental in the early detection of manufacturing defects in semiconductors. The increasing role of machine learning in optimizing semiconductor supply chains cannot be overlooked. Autonomous robots powered by AI are now being utilized for predictive maintenance in semiconductor factories.

Integrating AI to predict and prevent semiconductor failures

AI holds the potential to transform the semiconductor industry by predicting and preventing failures. By leveraging AI, the industry is witnessing an upsurge in the efficiency and effectiveness of semiconductor manufacturing processes. The integration of AI in semiconductor production has accelerated design and simulation, proving to be a game-changer in the industry.

Machine learning algorithms for optimizing robot maintenance tasks

Machine learning algorithms play a pivotal role in enhancing the performance of robots through predictive maintenance. They aid in the seamless analysis of data to pinpoint potential malfunctions, thereby optimizing maintenance tasks. The development of new robotic solutions for semiconductor testing and quality assurance through data science further underscores the impact of machine learning.

Emerging technologies : the role of AI in semiconductor production innovation

AI continues to spearhead innovation in semiconductor production. The adoption of AI in semiconductor manufacturing technologies has resulted in reduced production time and improved efficiency. Furthermore, the future trends in the semiconductor industry indicate a growing prevalence of human-robot collaboration, or “cobots”, in production environments. These cobots, powered by AI, are set to revolutionize the semiconductor production landscape, promising a future of unmatched efficiency and productivity.